16-28mm Oilfield Handling Tools XQ114/6YB Tubing Power Tong Anti Rust

16-28mm Oilfield Handling Tools XQ114/6YB Tubing Power Tong Anti Rust

| Application | Making Up/Breaking Out |

| Usage | Oilfield Handling Tools |

| Product | Sucker Rod |

| Standard | API |

| Process Type | Assy |

| Condition | New |

| Size | 16-28mm |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | drilling handling tools, drill pipe handling tools |

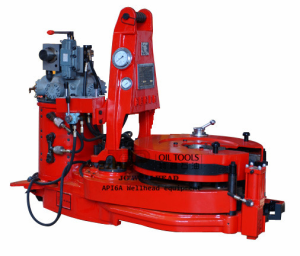

Oil Well Handling Tools Tubing Power Tong

Model XQ114/6YB(4 1/2") hydraulic power tong is an open type power tong for the making up and breaking out of tubing in well services. This product has the following features:- The tong is made up of master tong and backup tong, the master tong has a high and low gear train, the tong is compact, light and efficient.

- The master tong and backup hydraulics operate on valve banks independent of each other.

- There is an evident speed :high speed at top grade and large torque at low grade

- The tong has incorporated a new system of disc brake to hold the jaws to connection more effectively.

- Makeup and breakout are made easy with a simple turn to the reset knob on the tong and backup.

- The backup has been supplied with quick coupling hoses and connections for quick and easy installation for jobs where you need a backup and the backup can be removed in seconds for jobs

Specification of tubing power tong

| Model | - | XQ89/3Y3YC | XQ114/6YB | XQ140/12Y | XQ140/12Y-T |

|---|---|---|---|---|---|

| Applicable range | mm | 60-89 | 60-114 | 60-140 | 48-140 |

| in | 2 3/8 - 3 1/2 | 2 3/8 - 4 1/2 | 2 3/8 - 5 1/2 | 1.9 - 5 1/2 | |

| Applicable range | mm | 60-114 | 73-141.5 | 73-156 | 60-156 |

| in | 2 7/8 - 4 1/8 | 2 7/8 - 5 1/8 | 2 7/8 - 6 1/8 | 2 3/8 - 6 1/8 | |

| Hi-gear rated torque | kN.m | 1100 | 1500 | 2600 | 2600 |

| ft.lbf | 811 | 1106 | 1918 | 1918 | |

| Lo-gear rated torque | kN.m | 3300 | 6000 | 12000 | 12000 |

| ft.lbf | 2213 | 4425 | 8851 | 8851 | |

| High gear speed | rpm | 90 | 85 | 72 | 72 |

| Low gear speed | rpm | 30 | 20 | 14 | 14 |

| Rated pressure | MPa | 10 | 11 | 12 | 12 |

| psi | 1450 | 1595 | 1740 | 1740 | |

| Max. oil supply | L/min | 80 | 100 | 120 | 120 |

| gpm | 21 | 26 | 32 | 32 | |

| Size | mm | 650×430×550 | 750×500×600 | 1024×582×539 | 1050×620×900 |

| in | 25.6×16.9×21.7 | 29.5×19.7×23.6 | 40.3×22.9×21.2 | 41.3×24.4×35.4 | |

| Weight | kg | 158 | 220 | 480 | 480 |

| lb | 348 | 485 | 1060 | 1060 |

Cast Handling Tools Type B Manual Tong Complete With Jaw Assembly

Description

| Application | Oil & Gas Well Drilling Operation |

| Usage | Wellhead Handling Tools |

| Product | Manual Tong |

| Standard | API 7K |

| Process Type | Cast |

| Condition | New |

| Size | 3 1/2" - 13 3/8" |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Type B Manual Tong, Manual Tongs Drilling With Jaw Assembly, Cast Oilfield Handling Tools |

Type B Manual Tong Complete With Jaw Assembly For Handling Tools

The manual tongs are designed and manufactured in accordance with API Spec 7K-2010 Which is a useful tool applied to make up and break out drill pipes, coupling hoop of the drill pipe, joint, casings, casing hoops etc.When raise drill tool up and fall it down. Changing lug jaws and handling shoulders or hole can adjust the handling size of the tongs. According to the requirements of the usage different torque's tongs can be chosen. Manual Tong body is connected with joint pin on the boom and hangs over the well rigs through the balance head and adjustable square head screw.The pipe threads could be tightened or removed as soon as the steel wire rope which is fastened on the tongs line pin has been pulled firmly after the latch and the lug jaw have been looped and the pipes have been held by the tongs head.Part list of Type B Manual Tong

| Item# | Description |

|---|---|

| NP | Safety Handle Kit |

| NP | Tong Die Retainer Pin |

| Type "B" Tong Complete W/Short Lever Less Lug Jaws | |

| NP | Cotter Pin |

| NP | Removable Hinge Pin |

| Type "B" Tong Complete W/Standard Lever Less Lug Jaws | |

| 1-6 | Short Lever Assy. F/Type "B" Tong |

| 1 | Standard Lever Only F/Type "B" Tong |

| 1-6 | Standard Lever Assy. F/Type "B" Tong |

| 1 | Short Lever Only F/Type "B" Tong |

| 2 | Name Plate |

| 3 | Name Plate Screws |

| 4 | Grease Fitting |

| 5 | Tong Line Pin F/Type "B" Tong |

| 6 | Tong Line Pin Retainer |

| 7-10,12-15 | Set Back Hanger Assy. F/Type "B" Tong |

| 7-10,12-15 | Hanger Assy. F/Type "B" Tong |

| 7 | Hanger Only F/Type "B" Tong |

| 7 | Set Back Hanger Only F/Type "B" Tong |

| 8 | Balancing Screw |

| 9 | Balancing Screw Bolt |

| 10 | Lock Nut |

| 11 | Hinge Pin Retainer (Cotter) |

| 12 | Suspension Ring |

| 13 | Hanger Adjustment Screw |

| 14 | Hanger Jam Nut |

| 15 | Hanger Bolt |

| 16 | Safety Handle Kit |

| 17 | Lever Hinge Pin Block |

| 18 | Long Jaw F/Type "B" Tong |

| 18-29,31,36 | Long Jaw Assy. F/Type "B" Tong |

| 19 | Adjustable Stop |

| 20 | Adjustable Stop Plunger |

| 21 | Adjustable Stop Spring |

| 22 | Adjustable Stop Bolt |

| 23 | Adjustable Stop Bolt Nut |

| 24 | Cotter Pin |

| 25 | Booster Plunger |

| 26 | Booster Plunger Spring |

| 27 | Booster Plunger Retainer Plug |

| 28 | 1/2" x 1 1/4" x 5 7/8" Tong Die |

| 29 | Tong Die Retainer (Roll Pin) |

| 30 | Threader Hinge Pin |

| 31 | Hinge Pin Nut |

| 32,28,29,31,36 | Short Jaw Assy. |

| 32 | Short Jaw Only |

| 33 | Latch Only |

| 33,28,29,4 | Latch Assy. |

| 34,31,36 | Latch Assy. (Latch, HP Nut & Groove Pins) |

| 34 | Latch Only |

| 35 | Latch Spring |

| 36 | Groove Pin F/Hinge Pin Nut |

| 41F | 12 3/4" - 13" Lug Jaw Assembly |

| 41 | |

| 41D | 9" - 10 3/4" Lug Jaw Assembly |

| 41C | 6 5/8" - 9" Lug Jaw Assembly |

| 41B | 4 1/4" - 6 3/4" Lug Jaw Assembly |

| 41A | 3 1/2" - 5" Lug Jaw Assembly |

| 41G | 13 3/8" Lug Jaw Assembly |

| 41E | 11 3/4" Lug Jaw Assembly |

Hydraulic Casing / Tubing Power Tong For Oilfield Handling Tools

Description

| Application | Wellhead Handling Tools |

| Usage | Make Up And Break Out Drilling Tools |

| Product | TQ Series Casing Power Tong |

| Standard | API 7K |

| Condition | New |

| Brand | Rushi |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Hydraulic Casing Power Tong, Oilfield Tubing Power Tong, Alloy Steel Tubing Power Tong |

Hydraulic Casing Power Tong Assy and Tubing Power Tong Assy.

Hydraulic casing power tong and tubing power tong are used for making-up or breaking-out of casings or pipes in diameters of 4”--133/8” . The casing tongs and tubing tongs are designed and manufactured according to SY/T5074 and API Spec 7K .Features

l. Opening type, convenient and prompt to enter and slide off the working position, with an integral tong head of great strength and rigidity. 2. Double swing head jaws, very convenient to assemble and disassemble, with the best design for tangent-diameter ratio, ensuring the reliability of gripping and easy cam backslide. 3. Band brake of great moment, easy to operate and convenient to maintain and replace. 4. Notched gear new type sporting structure, greatly improving the strength and rigidity. 5. Wholly hydraulic mode. High torque motor of swing cylinder type will supply effective power. The power tong takes mechanical gear changing and its structure is simple and reliable.Specifications of Hydraulic Casing Power Tong and Tubing Power Tong

| Item | Description |

|---|---|

| 1 | Hydraulic Casing Power Tong Assy. Pipe Size 7"-20" O.D, 50,000 ft/lbs Max Torque, 7,700 ft/lbs Min Torque, 2,500 Psi. Includes Lift Valve, Safety Door Interlock, and Chain Hanger. Max Length: 80.25 Inches (203.8 cm) (Doors Closed). Height: 28" (71.1 cm). Overall Width: 50.5 Inches (128.3 cm). Chain Sling Not Included. |

| 2 | *ACCESSORIES: |

| - Torque Gauge Tension Assembly, 3 No | |

| - Jaw Die Kit For 13-3/8", 3 Set | |

| - Jaw Die Kit For 13-5/8", 3 Set | |

| - Jaw Die Kit For 14", 3 Set | |

| - Jaw Die Kit For 16", 3 Set | |

| - Jaw Die Kit For 18-5/8", 3 Set | |

| - Jaw Die Kit For 20", 3 Set | |

| 3 | Hydraulic Casing Power Tong Assy. Pipe Size 4-1/2"-14" O.D, 50,000 ft/lbs Max Torque, 12,560 ft/lbs Min Torque, 2,500 Psi. Includes Lift Valve, Safety Door Interlock, and Chain Hanger. Max Length: 70-3/8 Inches (179 cm). Height: 57" (145 cm) Including Chain Sling. Overall Width: 41 Inches (104 cm). |

| 4 | - Torque Gauge Tension Assembly, 5 No |

| - Jaw Die Kit For 7", 5 Set | |

| - Jaw Die Kit For 9-5/8", 5 Set | |

| - Jaw Die Kit For 10-3/4", 2 Set | |

| - Jaw Die Kit For 11-3/4", 2 Set | |

| - Jaw Die Kit For 13 3/8", 5 Set | |

| - Jaw Die Kit For 13 5/8", 2 Set | |

| - Jaw Die Kit For 14", 2 Set | |

| 5 | Hydraulic Tubing Power Tong Assy. Pipe Size 2-3/8"-8 5/8" O.D, 25,000 ft/lbs Max Torque, 5,100 ft/lbs Min Torque, 2,500 PSI. Includes Clincher Backup 8 5/8", Compression Load Cell-Style Backup, Lift Valve, Safety Door Interlock, and Solid Hanger. Max Length: 58" (147.3 cm). Height: 75-1/4" (191.1 cm). Overall Width: 36-3/4" (93.3 cm). |

| 6 | ACCESSORIES: |

| - Torque Gauge Compression Assembly, 4 No | |

| - Wraparound Jaw, 2-7/8"-3-1/2", 4 Set | |

| - Wraparound Jaw, 3.668”-5-1/2”, 4 Set | |

| - Wraparound Jaw, 5-3/4"-7-5/8", 4 Set | |

| - Gritface Wraparound Die, 4-1/8" x 3-1/2", 4 Set | |

| - Gritface Wraparound Die, 4-1/8" x 4", 2 Set | |

| - Gritface Wraparound Die, 6-3/8" x 4-1/2", 4 Set | |

| - Gritface Wraparound Die, 6-3/8" x 5", 4 Set | |

| - Gritface Wraparound Die, 6-3/8" x 5-1/2", 4 Set | |

| - Gritface Wraparound Die, 8-1/2" x 7", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 3-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 4", 2 Set | |

| - Die, Clincher Gritface, 8-5/8" x 4-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 5", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 5-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 7", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 7-5/8", 2 Set | |

| 7 | Hydraulic Tubing Power Tong Assy. Pipe Size 2-3/8"-5 1/2" O.D, 19,800 ft/lbs Max Torque, 3,960 ft/lbs Min Torque, 2,500 Psi. Includes Clincher Backup 5 1/2", Compression Load Cell-Style Backup, Lift Valve, Safety Door Interlock, and Solid Hanger. Max Length: 52 Inches (132.1 cm). Height: 60" (152.4 cm). Overall Width: 35" (89 cm). |

| 8 | - Torque Gauge Compression Assembly, 2 No |

| - Jaw Die Kit For 2-3/8", 2 Set | |

| - Jaw Die Kit For 2-7/8", 2 Set | |

| - Jaw Die Kit For 3-1/2", 2 Set | |

| - Jaw Die Kit For 4", 1 Set | |

| - Jaw Die Kit For 4-1/2", 2 Set | |

| - Jaw Die Kit For 5", 2 Set | |

| - Jaw Die Kit For 5-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 2-3/8", 2 Set | |

| - Die, Clincher, 5-1/2” x 2-7/8”, 2 Set | |

| - Die, Clincher, 5-1/2" x 3-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 4", 1 Set | |

| - Die, Clincher, 5-1/2" x 4-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 5", 2 Set | |

| - Die, Clincher, 5-1/2" x 5-1/2", 2 Set |

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

| Application | Wellhead Handling Tools |

| Usage | Make Up And Break Out Drilling Tools |

| Product | Pneumatic Spinning Wrench |

| Standard | API 7K |

| Condition | New |

| Function | Wellhead Automation Tools |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Oil Well Pneumatic Spinning Wrench, Spinning Wrench Wellhead Handling Tools, Wellhead Handling Spinning Wrench |

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

Q Series Pneumatic Spinning Wrench is a pneumatically power tool capable of spinning drill pipe and collar from 31/2 to 10 inches O.D., especially used in the mechanized operation of drilling machines in shore and land oilfields instead of previous “chain” and “cord”. It’s operated more safety and with less labor power, and more efficiency. It’s more convenience to fetch core and deal with the problem underwell. The wrench’s spinning procedure is as follows: first position the wrench vertically to a joint about 11.8-19.7 inch, or just about the upset, the wrench is now swung onto pipe and it’s four drive rollers on the head clamp the pipe. Turn on air valve of air spring, to make rollers upon drill pipe, then push/pull the handle of air motors valve. Left and right motors work, and drive rollers rotate through its reducer mechanism. Drill pipe rotates for its friction. So drill pipe joint will be spinned in or out.Sepecification of Pneumatic Spinning Wrench

| Model | Q254-250 | Q254-300Y | Q254-300Y | |

|---|---|---|---|---|

| Drive mode | - | Pneumatic | - | Hydraulic |

| Size range | mm | 88.9-139.7 | 88.9-254 | 88.9-254 |

| in | 3 1/2 - 5 1/2 | 3 1/2 - 10 | 3 1/2 - 10 | |

| Air pressure | MPa | 0.5-0.9 | 0.5-0.9 | - |

| psi | 72-130 | 72-130 | - | |

| Pressure rating | Mpa | - | - | 14 |

| psi | - | - | 2000 | |

| Max. brake torque | Nm | 2000 | 2500 | 3000 |

| ft.lbf | 1475 | 1840 | 2210 | |

| Speed | RPM | 0-90 | 0-120 | 0-95 |

| Air consumption | m3/min | 10.3 | 15 | - |

| ft3/min | 360 | 529 | - | |

| Flow | LPM | - | - | 120-140 |

| GPM | - | - | 32-37 | |

| Size | mm | 1400×530×835 | 1250×570×465 | 1100×560×700 |

| in | 55×21×33 | 49×23×18 | 44×23×28 | |

| Weight | Kg | 378 | 440 | 400 |

| lb | 833 | 971 | 880 |

Q13 3/8-25 1/2/35 API 7K Manual Casing Tong Drill Pipe Handling Tools Alloy Steel

| Application | Making Up/Breaking Out Casing |

| Usage | Oilfield Handling Tools |

| Product | Casing |

| Standard | API 7K |

| Process Type | Cast |

| Condition | New |

| Size | Q 13 3/8 - 25 1/2 - 35 |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | drill pipe handling equipment, drill pipe handling tools |

Oil Well Handling Tools Manual Tong Type DB

The manual tongs are designed and manufactured in accordance with the National Standard for the Petroleum and National Gas Industry GB/T17744, SY/T5074-2012“Elevator links,elevators,tongs”which is a useful tool applied to make up and break out drill pipes, coupling hoop of the drill pipe ,joint, casings , casings hoops etc. When raise drill tool up and fall it down. Changing lug jaws and handling shoulders or hole can adjust the handling size of the tongs According to the requirements of the usage different torque’s tongs can be chosen.Q13 3/8-25 1/2/35 API 7K Manual Casing Tong Drill Pipe Handling Tools Alloy Steel

| Model | No. of Latch Lug Jaw | Size Range in | Rated Torque (kN·m) |

|---|---|---|---|

| 13-3/8”~25-1/2”-35 | 9, 8 | 13-3/8”~14-1/2” | 35 |

| 8, 7 | 14-1/2”~16” | ||

| 8, 9, 9 | 16”~17-1/2” | ||

| 8, 9, 7 | 17-1/2”~19” | ||

| 7, 8, 7 | 19”~20” | ||

| 9, 8, 9, 7 | 20”~21-1/2” | ||

| 9, 7, 8, 7 | 21-1/2”~23” | ||

| 9, 9, 8, 7, 7 | 24”~25-1/2” | ||

| 9, 8, 7, 7, 7 | 25-1/2”~27” | ||

| 8, 7, 7, 7, 7 | 27”~28-1/2” | ||

| 9, 9, 8, 7, 7, 8 | 28-1/2”~30” | ||

| 9, 7, 7, 7, 7, 8 | 9, 7, 7, 7, 7, 8 | 30” | |

| Model | No. of Latch Lug Jaw | Size Range in | Rated Torque (kN·m) |

| 25-1/2”~36”-35 | 9, 8, 7, 7, 7 | 25-1/2”~27” | 55 |

| 8, 7, 7, 7, 7 | 27”~28-1/2” | ||

| 9, 9, 7, 7, 7, 8 | 28-1/2”~30” | ||

| 9, 7, 7, 7, 7, 8 | 30”~31-5/8” | ||

| 8, 9, 8, 9, 7, 7 | 31-1/2”~33” | ||

| 7, 9, 8, 9, 9, 7, 8, 9 | 33”~34-1/2” | ||

| 8, 7, 7, 9, 9, 8, 8, 8 | 34-1/2”~36” |

ZQ Series Handling Tools Oilfield Drill Pipe Hydraulic Power Tong API

ZQ Series Handling Tools Oilfield Drill Pipe Hydraulic Power Tong API

| Category | Details |

|---|---|

| Application | Drilling Service |

| Usage | Oilfield Handling Tools |

| Product | Drill Pipe Power Tong |

| Standard | API 7K |

| Condition | New |

| Function | Make Up and Breaking Out of Drill Pipes |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Handling Hydraulic Power Tong, Drill Pipe Hydraulic Power Tong, API Compliant |

ZQ Series Drill Pipe Hydraulic Power Tong API Oilfield Handling Tools

ZQ Drill Pipe Power Tong is an ideal wellhead handling tool for oil and gas well drilling operation, the power tong is widely applied in making-up and breaking-out for well drilling and repairing on offshore and land. Open-throat design of the ZQ series with high mobility allows escaping from drilling pipe freely. The tong is a combination of spinning tong and torque tong. It substitutes cathead, suspension tong and spinning rope in making-up and breaking-out. The tongs are designed and manufactured according to API Spec 7KSEPCIFICATION OF DRILL PIPE POWER TONG

| Model | ZQ127-25 | ZQ162-50 | ZQ203-100 | ZQ203-125 | |

|---|---|---|---|---|---|

| Size range | mm | 65-127 | 85-162 | 127-203 | 127-203 |

| in | 2 3/8 coupling - 3 1/2 coupling | 2 3/8 coupling - 5 coupling | 3 1/2 coupling - 8 body | 3 1/2 coupling - 8 body | |

| Max.torque | KN.m | 25 | 50 | 100 | 125 |

| ft.lbf | 18440 | 36880 | 73750 | 92200 | |

| Speed(High ger) | rpm | 65 | 60 | 40 | 40 |

| Speed(Low ger) | rpm | 10.5 | 4.1 | 2.7 | 2.7 |

| Air pressure | Mpa | 0.5-1 | |||

| psi | 72-144 | ||||

| Pressure rating | Mpa | 12 | 16 | 16.6 | 20 |

| psi | 1740 | 2320 | 2400 | 2900 | |

| Flow rating | L/min | 120 | 120 | 114 | 114 |

| gpm | 31.7 | 31.7 | 30 | 30 | |

| Shifting distance | mm | 1000 | 1000 | 1500 | 1500 |

| in | 39.4 | 39.4 | 59 | 59 | |

| Lifting distance | mm | - | 0-440 | 0-430 | - |

| in | - | 0-17.3 | 0-17 | - | |