Forging Tubing Head Spool 11“ X 7 1/16“ X 3 1/8“ X 3 1/2“ EUE Top Botto 3000 PSI

Forging Tubing Head Spool 11`` X 7 1/16`` X 3 1/8`` X 3 1/2`` EUE Top Botto 3000 PSI

Description

| Application: | Oil Well Drilling Operation | Usage: | Wellhead Equipment For Flow Control |

| Material Class: | AA | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Tubing Head Spool | Working Pressure: | 3000 Psi |

| Flange Size: | 11" X 7 1/16" X 3 1/8" X 3 1/2" EUE | Process Type: | Forging |

| Highlight: | 3000 PSI Tubing Head Spool, Forging Tubing Head Spool, Tubing Wellhead Casing Head | ||

Tubing Head Spool 11`` x 7 1/16`` x 3 1/8`` x 3 1/2``EUE top&bottom - 3000 PSI, AA, PU, PSL2, PR2

The tubing head spools for oil & gas well operation are designed and manufactured strictly according to API 6A, NACE MR-0175 standard. The Tubing head is a spool with flange top, flanged bottom and two side outlets. It also can be called tubing spool.

Features of Tubing Head Spool

- Tubing head spool features a versatile straight bore design for single and multiple completions

- Tubing hanger and top flange of the tubing head spool are designed to run cable through.

- Several control ports are available for connecting pipeline.

- The tubing head spool is made of forged or special smelt steel, providing high bearing strength, safety and reliability.

Specification of Tubing Head Spool

| SECTION C : Tubing Head Spool 11" x 7 1/16" x 3 1/8" x 3 1/2"EUE top&bottom - 3000 PSI, AA, PU, PSL2, PR2 | |||

| 1 | Tubing Head Spool 11" x 3000 PSI WP flanged bottom - 7 1/16" x 3000 PSI WP flanged top, with two 2 1/16" x 3000 PSI studded side outlets studs & nuts included, with thread 1 1/2"LP for VR plug, 45º landing shoulder for tubing hanger area, c/w lock down screws with lock down threads outside from the fluid well area, prepared to receive wear bushing. |

1 | API 6A 60K- AA A487-4C |

| 2 | Tubing Hanger, with extended neck, double sealing: - 7 1/16" x 3 1/2"EUE top&bottom - with thread 3" HBPV-UZT-LH |

1 | API 6A 75K- AA AISI 4130 |

| 3 | 5" Double “P” Seal | 1 | API 6A 75K- AA NBR |

| 4 | Gate Valve 2 1/16" - 3000 PSI WP, flanged ends, full bore, through conduit, hand-wheel operated. | 2 | API 6A 60K- AA A487-4C Trim AA |

| 5 | Companion Flange 2 1/16" x 2"LP - 3000 PSI. | 1 | API 6A 60K- AA AISI 4130 |

| 6 | Blind Flange 2 1/16" - 3000 PSI. | 1 | API 6A 60K- AA AISI 4130 |

| 7 | Bull Plug 2"LP - 1/2"-14NPT | 1 | API 6A 60K- AA AISI 4130 |

| 8 | Needle Valve ½'' NPT male x female - 10000 PSI WP | 1 | - |

| 9 | Pressure Gauge, 0…3000 PSI, 4 ½'' or 6 ¼'' face | 1 | - |

| 10 | Ring Gasket API R45, Cd or Zn plated, for 7 1/16" x 3000 PSI Flange | 1 | API-6A/S4 |

| 11 | Ring Gasket API R31, Cd or Zn plated, for 3 1/8" x 3000 PSI Flange | 1 | API-6A/S4 |

| 12 | Ring Gasket API R24, Cd or Zn plated, for 2 1/16" x 3000 PSI Flange | 4 | API-6A/S4 |

| 13 | Set of Studs with two Nuts for 2 1/16" x 3000 PSI Flange | 2 | API 20E- BSL1 B7/2H |

| SECTION D : Tubing Head Adapter 7 1/16" x 3 1/8" - 3000 PSI, AA, PU, PSL2, PR2 | |||

| 1 | Tubing Head Adapter 7 1/16" x 3000 PSI WP flanged bottom - 3 1/8" x 3000 PSI WP studded top, (including studs & nuts), prepared for the above extended neck tubing hanger. | 1 | API 6A 60K- AA AISI 4130 |

| 2 | Ring Gasket API R31, Cd or Zn plated, for 3 1/8" x 3000 PSI Flange | 1 | API-6A/S4 |

| 3 | Set of Studs with two Nuts for 7 1/16" x 3000 PSI Flange | 1 | API 20E- BSL1 B7/2H |

Forging Wellhead Christmas Tree Assembly 3000 Psi For Drilling well Completion

Product Details:

| Brand Name: | JC Wellhead |

| Certification: | API 6A |

| Model Number: | API 6A Wellhead Assembly |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

| Packaging Details: | Polywood case for land, air, ocean shipment |

| Delivery Time: | 30-45 days |

| Payment Terms: | T/T, L/C, D/P |

| Supply Ability: | 100 sets / month Forging Wellhead Christmas Tree Assembly 3000 Psi For Drilling well Completion |

Description

| Application: | Oil & Gas Well Drilling And Completion Operation | Usage: | Wellhead Flow And Pressure Control |

| Material Class: | DD-NL | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Casing Head Spool Assembly | Working Pressure: | 3000 Psi |

| Nominal Flange Size: | 4 1/16" X 5M | Process Type: | Forging |

| Highlight: | 3000 Psi Well Head Assembly, Completion Wellhead Christmas Tree, Forging Wellhead Christmas Tree | ||

Well Head Assembly 3000 Psi Drilling And Well Completion Wellheads

The Wellhead Equipment is designed and manufactured according to API 6A Specification, The wellhead equipment is applied for oil & gas well drilling operation and well completion. Normally the oil & gas wellhead equipment consists of casing head, casing head spool, tubing head spool and wellhead Christmas Tree.

Oilfield Drilling 5000psi Wellhead Christmas Tree Flow Control

Product Details:

| Brand Name: | JC Wellhead |

| Certification: | API 6A |

| Model Number: | 5000 psi Wellhead Equipment |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

| Packaging Details: | Polywood case for land, air, ocean shipment |

| Delivery Time: | 30-45 days |

| Payment Terms: | T/T, L/C, D/P |

| Supply Ability: | Supply Ability |

Oilfield Drilling 5000psi Wellhead Christmas Tree Flow Control

Description

| Application: | Oilfield Drilling Operation | Usage: | Oil Well Flow Control Equipment |

| Material: | EE | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Specification: | 13-5/8" 5K | Working Pressure: | 5000 Psi |

| Highlight: | 5000psi Wellhead Christmas Tree, Oilfield Drilling Wellhead Christmas Tree, Flow Control Wellhead Christmas Tree | ||

Wellhead Christmas Tree with Casing Head Tubing Head API 6A

The wellhead equipment is composed of wellhead Christmas tree, Casing head and tubing head spool. The wellhead equipment is conformed with API 6A, is the important component at the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The wellhead assembly is a kind of safe, reliable wellhead equipment which is used for fixing drilling wellhead, connecting wellhead casing string, sealing and controlling annular space between pipes, hanging pipes, controlling wellhead pressure and adjust the flow rate of oil and gas. It is applicable to all the casing and tubing programs and connection types. The wellhead X tree can be used to guide oil to pipe and to close oil well if necessary. The wellhead Christmas tree can be used to guide oil to pipe and to close oil well if necessary, during the oilfield drilling operation.

Detailed specification of Wellhead Assembly

| WELLHEAD DESIGN 5K PSI SPOOL | ||

| SR NO. | QTY | DESCRIPTION |

| CASING HEAD HOUSING: 21 1/4 - 2K PSI C/W SOW | ||

| 1 | 1 | CASING HEAD HOSUING: 21 1/4 - 2K PSI FLANGED TOP X 20" SLIP ON WELD BOTTOM WITH 2" L.P ONE # OUTLET, API 6A, PSL-2, PR-2, MATERIAL FF, TEMP. "U". |

| 2 | 1 | RING GASKET STD R-73 |

| 3 | 1 | CASING HANGER:TYPE IC-2 20" X 13 3/8" O.D CASING WITH SEAL, PSL-2, PR-2, MATERIAL FF, TEMP. "U". |

| 4 | 1 | GATE VALVE: 2 1/16"-3K WITH 2" LP ENDS. PSL-2, PR-2, MATERIAL-FF |

| 5 | 1 | NIPPLE 2" API LP X 6" LONG |

| 6 | 1 | BULL PLUG 2" API LP X 3-3/4" LONG,TAPPED 1/2'' NPT |

| 7 | 1 | BULL PLUG 2" API LP X 3-3/4" LONG |

| 8 | 1 | GAUGE: PRESSURE 2K PSI, 4-1/2" DIAMETER. 1/2" NPT. |

| 9 | 1 | NEEDLE VALVE, ANGLE, 5K PSI WP, 1/2" NPT MALE THREAD INLET X FEMALE THREAD OUTLET |

| 10 | 24 | STUDS , CONT. THD 1 5/8" 11-3/4" LONG |

| 11 | 48 | NUTS HEAVY-HEX 1.625-8 |

| 12 | 1 Each | TEST PLUG AND WEAR BUSHING , CONNECTION 4-1/2'' IF FOR 21-1/4'' CASING HEAD SPOOL |

| CASING HEAD SPOOL: 21-1/4" 2K X 13-5/8" 5K | ||

| 13 | 1 | CASING HEAD SPOOL IC-2-BP: 21 1/4" 2K FLANGE BOTTOM X 13-5/8" 5K TOP WITH TWO # 2-1/16" 5K STUDDED OUTLETS. PREPARED FOR VR THREAD WITH DOUBLE PRESSURE SEALS TO SEAL ON 13 3/8" OD CSG. API 6A PSL-2, PR-2, MATERIAL FF, TEMPERATURE "U". |

| 14 | 1 | RING GASKET. API TYPE BX-160, PRESSURE ENERGISED STEEL |

| 15 | 1 | VALVE REMOVAL PLUG, 1-1/2" VEE TBG THD. |

| 16 | 1 | CSG HANGER : IC-2 13 5/8" X 9 5/8" WITH SEAL,API 6A, PSL-2, PR-2, MATERIAL FF, TEMPERATURE "U". |

| 17 | 16 | STUDS , CONT. THD 1.625"-8 X 12.5" LONG WITH NUTS |

| 18 | 32 | NUTS HEAVY-HEX 1.625"-8 |

| 19 | 2 | GATE VALVE: 2 1/16"-5K WITH DOUBLE FLANGE ENDS, PSL-2, PR-2, MATERIAL-FF, TEMP "U". |

| 20 | 2 | RECESSED BLIND FLANGE 2 1/16" API 5K WITH 2" L.P WITH 1/2" NPT. |

| 21 | 1 | NEEDLE VALVE, ANGLE, 5K PSI WP, 1/2" NPT MALE THREAD INLET X FEMALE THREAD OUTLET |

| 22 | 1 | GAUGE PRESSURE 5K PSI, 4-1/2" DIAMETER. 1/2" NPT. |

| 23 | 3 | RING GASKET RX-24 |

| 24 | 8 | STUDS , CONT. THD , 0.875''-9 X 6'' LONG |

| 25 | 16 | NUTS HEAVY-HEX 0.875"-9 |

| 26 | 1 Each | TEST PLUG AND WEAR BUSHING , CONNECTION 4-1/2'' IF FOR 13-5/8'' CASING HEAD SPOOL |

| CASING SPOOL: 13 5/8" 5K X 11" 5K. | ||

| 27 | 1 | CSG SPOOL: IC-2-L, 13-5/8" 5K X 11" 5K WITH TWO # 2-1/16" 5K STUDDED OUTLETS, VR THREAD WITH DOUBLE PRESSURE "P" SEALS TO SEAL ON 9-5/8" CSG OD. API 6A PSL-3, PR-2, MATERIAL FF, TEMPERATURE "U". |

| 28 | 2 | RING GASKET, API, RX-54 |

| 29 | 1 | CSG HANGER TYPE IC-2, 11" X 7" WITH SEAL, PSL-2, PR-2, MATERIAL FF, TEMPERATURE U. |

| 30 | 1 EACH | DUAL SPLIT TYPE TUBING HANGER WITH TUBINGS SIZE 3-1/2" AND 2-7/8'' WITH TOP FLANGE SIZE 11" |

| 31 | 2 | GATE VALVE: 2-1/16" 5K WITH DOUBLE FLANGE ENDS, PSL-2, PR-2, MATERIAL-FF, TEMP "U". |

| 32 | 1 | NEEDLE VALVE, ANGLE, 5K PSI WP, 1/2" NPT |

| 33 | 1 | VALVE REMOVAL PLUG, 1-1/2" VEE TBG THD. |

| 34 | 12 | STUDS , CONT. THD 1.875"-8 X 13.75" LONG |

| 35 | 24 | NUTS HEAVY-HEX 1.875"-8 |

| 36 | 2 | RECESSED BLIND FLANGE 2-1/16" API 5K WITH 1/2" NPT |

| 37 | 1 | GAUGE PRESSURE, 4-1/2'' DIA FOR 5K PSI. |

| 38 | 3 | RING GASKET RX-24 |

| 39 | 8 | STUDS , CONT. THD , 0.875''-9 X 6'' LONG |

| 40 | 16 | NUTS HEAVY-HEX 0.875"-9 |

| 41 | 1 | BACK PRESSURE VALVE FOR DUAL SPLITTER HANGER SIZE 3-1/2'' AND 2-7/8'' TUBINGS |

| 42 | 1 Each | TEST PLUG AND WEAR BUSHING , CONNECTION 4-1/2'' IF FOR 11'' CASING HEAD SPOOL |

| SR NO. | QTY | DESCRIPTION |

| TUBING SPOOL: 11" 5K X 7-1/16" 5K | ||

| 1 | 1 | TBG SPOOL: 11"-5K X 7-1/16"-5K WITH TWO # 2-1/16" 5-K STUDDED OUTLETS. VR THD OUTLETS WITH DOUBLE PRESSURE''P '' SEAL BTM FOR 7" CSG. API 6A PSL-2, PR-2, MATERIAL FF, TEMPERATURE "U". |

| 2 | 1 | RING GASKET RX-46 |

| 3 | 1 | TBG HANGER : 7-1/16'' X 3-1/2'' WITH SEAL PSL-2, PR-2, MATERIAL FF, TEMPERATURE U. |

| 4 | 2 | GATE VALVE: 2 1/16" 5K WITH DOUBLE FLANGE ENDS, PSL-2, PR-2, MATERIAL-FF, TEMP "U". |

| 5 | 1 | NEEDLE VALVE, ANGLE, 5K PSI WP, 1/2" NPT MALE THREAD INLET X FEMALE THREAD OUTLET |

| 6 | 12 | STUDS , CONT. THD 1-3/8" X 10-3/4" LONG |

| 7 | 1 | GAUGE PRESSURE, 4-1/2'' DIA FOR 5K PSI. |

| 8 | 24 | NUTS HEAVY-HEX 1-3/8'' |

| 9 | 1 Each | TEST PLUG AND WEAR BUSHING , CONNECTION 3-1/2'' IF FOR 7-1/16'' TUBING HEAD SPOOL |

| 10 | 2 | RECESSED BLIND FLANGE 2 1/16" API 5K WITH 1/2" NPT |

| 11 | 2 | RING GASKET: |

| 12 | 24 | STUDS , CONT. THD , 0.875''-9 X 6'' LONG |

| 13 | 48 | NUTS HEAVY-HEX 0.875"-9 |

| 14 | 1 | BACK PRESSURE VALVE FOR TUBING HANGER 3-1/2'' |

High Pressure API 6A Data Header For Surface Well Testing Service

Description

| Application: | Surface Well Testing Operation | Usage: | Measure And Monitor Pressure |

| Material: | AISI 4130 Alloy Steel | Production Level: | PLS 3 |

| Type: | Integral Piping Data Header | Standard: | API 6A |

| Product Name: | Well Test Data Header | Working Pressure: | 10000 Psi |

| Production Level: | PSL 3 | Working Condiction: | Standard Serive Or Sour Service |

| Highlight: | Alloy Steel Well Test Data Header, Data Header API 6A, Surface Well Testing Data Header | ||

High Pressure API 6A Data Header For Surface Well Testing Service

The high pressure data header is designed and manufactured according to API 6A specification. The data headers are mainly applied for surface well testing service, which is a piping component with several ports along or around its length.The Well Testing Data Header is mounted in the production flow path upstream of well test choke manifold for sampling wellbore production parameter and normally situated immediately upstream of the choke and provides access to the flowstream for sampling, monitoring of pressure and temperature, sand erosion monitoring, and chemical injection, also called Injection header.Technical parameter of Data Header

1.Material:AlS14130 Forged 2.Maferial class:DD-NL 3.PSL-3 4.Temperature Rating:PU 5.Rating Working Pressure:10000PSI 6.Support legs are included. 7.Manufacturing standard:APl6A/NACE MR0175 8.APl6A monogrammed. 9.Estimated net weight:105kgs 10.Documents Supplied: ∂.Material Certificate b.Heat freatment Report C.UT Report d.PI reportSpecification of 3" x 10000psi Data Header

| WORKING PRESSURE, psi | 10000 |

| TEST PRESSURE, psi | 15000 |

| TEMPERATURE OPERATION, degF | 250 |

| ID, pulg | 3 |

| LONG, ft | 2 |

| PORT | 4 port, 1/2" NPT |

| INLET | 3 inch FIG 602 |

| OUTLET | 3 inch FIG 602 |

Hydraulic Casing / Tubing Power Tong For Oilfield Handling Tools

Description

| Application | Wellhead Handling Tools |

| Usage | Make Up And Break Out Drilling Tools |

| Product | TQ Series Casing Power Tong |

| Standard | API 7K |

| Condition | New |

| Brand | Rushi |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Hydraulic Casing Power Tong, Oilfield Tubing Power Tong, Alloy Steel Tubing Power Tong |

Hydraulic Casing Power Tong Assy and Tubing Power Tong Assy.

Hydraulic casing power tong and tubing power tong are used for making-up or breaking-out of casings or pipes in diameters of 4”--133/8” . The casing tongs and tubing tongs are designed and manufactured according to SY/T5074 and API Spec 7K .Features

l. Opening type, convenient and prompt to enter and slide off the working position, with an integral tong head of great strength and rigidity. 2. Double swing head jaws, very convenient to assemble and disassemble, with the best design for tangent-diameter ratio, ensuring the reliability of gripping and easy cam backslide. 3. Band brake of great moment, easy to operate and convenient to maintain and replace. 4. Notched gear new type sporting structure, greatly improving the strength and rigidity. 5. Wholly hydraulic mode. High torque motor of swing cylinder type will supply effective power. The power tong takes mechanical gear changing and its structure is simple and reliable.Specifications of Hydraulic Casing Power Tong and Tubing Power Tong

| Item | Description |

|---|---|

| 1 | Hydraulic Casing Power Tong Assy. Pipe Size 7"-20" O.D, 50,000 ft/lbs Max Torque, 7,700 ft/lbs Min Torque, 2,500 Psi. Includes Lift Valve, Safety Door Interlock, and Chain Hanger. Max Length: 80.25 Inches (203.8 cm) (Doors Closed). Height: 28" (71.1 cm). Overall Width: 50.5 Inches (128.3 cm). Chain Sling Not Included. |

| 2 | *ACCESSORIES: |

| - Torque Gauge Tension Assembly, 3 No | |

| - Jaw Die Kit For 13-3/8", 3 Set | |

| - Jaw Die Kit For 13-5/8", 3 Set | |

| - Jaw Die Kit For 14", 3 Set | |

| - Jaw Die Kit For 16", 3 Set | |

| - Jaw Die Kit For 18-5/8", 3 Set | |

| - Jaw Die Kit For 20", 3 Set | |

| 3 | Hydraulic Casing Power Tong Assy. Pipe Size 4-1/2"-14" O.D, 50,000 ft/lbs Max Torque, 12,560 ft/lbs Min Torque, 2,500 Psi. Includes Lift Valve, Safety Door Interlock, and Chain Hanger. Max Length: 70-3/8 Inches (179 cm). Height: 57" (145 cm) Including Chain Sling. Overall Width: 41 Inches (104 cm). |

| 4 | - Torque Gauge Tension Assembly, 5 No |

| - Jaw Die Kit For 7", 5 Set | |

| - Jaw Die Kit For 9-5/8", 5 Set | |

| - Jaw Die Kit For 10-3/4", 2 Set | |

| - Jaw Die Kit For 11-3/4", 2 Set | |

| - Jaw Die Kit For 13 3/8", 5 Set | |

| - Jaw Die Kit For 13 5/8", 2 Set | |

| - Jaw Die Kit For 14", 2 Set | |

| 5 | Hydraulic Tubing Power Tong Assy. Pipe Size 2-3/8"-8 5/8" O.D, 25,000 ft/lbs Max Torque, 5,100 ft/lbs Min Torque, 2,500 PSI. Includes Clincher Backup 8 5/8", Compression Load Cell-Style Backup, Lift Valve, Safety Door Interlock, and Solid Hanger. Max Length: 58" (147.3 cm). Height: 75-1/4" (191.1 cm). Overall Width: 36-3/4" (93.3 cm). |

| 6 | ACCESSORIES: |

| - Torque Gauge Compression Assembly, 4 No | |

| - Wraparound Jaw, 2-7/8"-3-1/2", 4 Set | |

| - Wraparound Jaw, 3.668”-5-1/2”, 4 Set | |

| - Wraparound Jaw, 5-3/4"-7-5/8", 4 Set | |

| - Gritface Wraparound Die, 4-1/8" x 3-1/2", 4 Set | |

| - Gritface Wraparound Die, 4-1/8" x 4", 2 Set | |

| - Gritface Wraparound Die, 6-3/8" x 4-1/2", 4 Set | |

| - Gritface Wraparound Die, 6-3/8" x 5", 4 Set | |

| - Gritface Wraparound Die, 6-3/8" x 5-1/2", 4 Set | |

| - Gritface Wraparound Die, 8-1/2" x 7", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 3-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 4", 2 Set | |

| - Die, Clincher Gritface, 8-5/8" x 4-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 5", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 5-1/2", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 7", 4 Set | |

| - Die, Clincher Gritface, 8-5/8" x 7-5/8", 2 Set | |

| 7 | Hydraulic Tubing Power Tong Assy. Pipe Size 2-3/8"-5 1/2" O.D, 19,800 ft/lbs Max Torque, 3,960 ft/lbs Min Torque, 2,500 Psi. Includes Clincher Backup 5 1/2", Compression Load Cell-Style Backup, Lift Valve, Safety Door Interlock, and Solid Hanger. Max Length: 52 Inches (132.1 cm). Height: 60" (152.4 cm). Overall Width: 35" (89 cm). |

| 8 | - Torque Gauge Compression Assembly, 2 No |

| - Jaw Die Kit For 2-3/8", 2 Set | |

| - Jaw Die Kit For 2-7/8", 2 Set | |

| - Jaw Die Kit For 3-1/2", 2 Set | |

| - Jaw Die Kit For 4", 1 Set | |

| - Jaw Die Kit For 4-1/2", 2 Set | |

| - Jaw Die Kit For 5", 2 Set | |

| - Jaw Die Kit For 5-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 2-3/8", 2 Set | |

| - Die, Clincher, 5-1/2” x 2-7/8”, 2 Set | |

| - Die, Clincher, 5-1/2" x 3-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 4", 1 Set | |

| - Die, Clincher, 5-1/2" x 4-1/2", 2 Set | |

| - Die, Clincher, 5-1/2" x 5", 2 Set | |

| - Die, Clincher, 5-1/2" x 5-1/2", 2 Set |

Hydraulic Double Ram Blowout Preventer / Wireline BOP For Well Control

| Application: | Oil Well Pressure Control | Usage: | Slickline Operation |

| Material: | Alloy Steel Forging | Production Level: | PLS 1-3 |

| Temperature Class: | T | Standard: | API 16A |

| Product Name: | Hydraulic Double Ram BOP | Specification: | FZ35-35 |

| Working Condition: | Standard | Delivery Of BOP: | 20 Days |

| Highlight: | Hydraulic Double Ram Blowout Preventer, Double Ram Wireline BOP, Oil Well Control Wireline BOP | ||

Specification of Hydraulic double RAM BOP

| Model | WP (Psi) | ID (in.) | Sealed String Max. OD (in) | Connection | Service Environment | Temperature |

| FZ18-21 | 3000 | 7 1/16” | 3 1/2” | 7 1/16" (Studded) Flange | Crude oil, Water, Natural gas with H2S | T-20 (-29 ℃ ~ + 121 ℃) |

| 2FZ18-21 | 3000 | 7 1/16” | 3 1/2” | 7 1/16" (Studded) Flange | ||

| FZ18-35 | 5000 | 7 1/16” | 3 1/2” | 7 1/16" (Studded) Flange | ||

| 2FZ18-35 | 5000 | 7 1/16” | 3 1/2” | 7 1/16" (Studded) Flange | ||

| FZ18-70 | 10000 | 7 1/16” | 3 1/2” | 7 1/16"(Studded) Flange | ||

| 2FZ18-70 | 10000 | 7 1/16” | 3 1/2” | 7 1/16" (Studded) Flange | ||

| FZ23-14 | 2000 | 9” | 5 1/2” | 9"(Studded) Flange | ||

| FZ23-21 | 3000 | 9” | 5 1/2” | 9" (Studded) Flange | ||

| FZ23-35 | 5000 | 9” | 5 1/2” | 9" (Studded) Flange | ||

| 2FZ23-35 | 5000 | 9” | 5 1/2” | 9" (Studded) Flange | ||

| FZ28-21 | 3000 | 11” | 7” | 11" (Studded) Flange | ||

| FZ28-35 | 5000 | 11” | 7” | 11" (Studded) Flange | ||

| 2FZ28-35 | 5000 | 11” | 7” | 11" (Studded) Flange | ||

| FZ35-35 | 5000 | 13 5/8” | 9 5/8” | 13 5/8" (Studded) Flange | ||

| 2FZ35-35 | 5000 | 13 5/8” | 9 5/8” | 13 5/8" (Studded) Flange | ||

| FZ35-70 | 10000 | 13 5/8” | 9 5/8” | 13 5/8" (Studded) Flange | ||

| 2FZ35-70 | 10000 | 13 5/8” | 9 5/8” | 13 5/8" (Studded) Flange |

Hydraulic Wireline BOP Oil Well Blowout Preventer For Slick Line Operation

| Application: | Oil Well Pressure Control | Usage: | Oil Well Slick Line Operation |

| Material: | Alloy Steel Forging | Production Level: | PLS 1-3 |

| Temperature Class: | T | Standard: | API 16A |

| Product Name: | Wireline BOP | Specification: | FZ65-35/70/105 |

| Working Condition: | Standard | Delivery Of BOP: | 20 Days |

| Highlight: | Hydraulic Oil Well Blowout Preventer, BOP Oil Well Blowout Preventer, Wireline Oil Well Blowout Preventer | ||

API Wireline BOP for Slick Line Operation Hydraulic Cable Blowout Preventer

The Cable BOP adopts circular ram with small force and simple structure. It has two kinds of open and close mode: manual control and hydraulic control. It has five structures: single ram, double ram, three ram, manual control and hydraulic control. The connection type is union. It connects with wellhead or other BOP by adapter flange.

The wireline BOPhas simple structure, convenient application and maintenance, small volume, light weight, high pressure bearing, hydraulic remote control and simple and reliable operation. The BOP is mainly composed of main casing, and ram assembly piston, hydraulic cylinder, lead screw, end cap, hand wheel and other spare parts, which are moving in the main casing in opposite direction.

Specification of 3 1/2`` x 5000 psi Polished rod BOP

| Model | Nominal Dia. | Working pressure | Structure of RAM | Operated type |

| FZ65-35/70/105 | 2 9/16" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

| FZ76-35/70/105 | 3" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

| FZ120-35/70/105 | 4 3/4" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

| FZ140-35/70/105 | 5 1/2" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

| FZ160-35/70/105 | 6 5/16" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

| FZ180-35/70/105 | 7 1/16" | 35/70/105 | Single,double,triple | Manual, Hydraulic |

Integral Alloy Steel Pipe Fittings Chiksan Swivel Joint For Oil Well Cementing Operation

Integral Alloy Steel Pipe Fittings Chiksan Swivel Joint For Oil Well Cementing Operation

Description| Application: | Oil Well Cementing Operation | Usage: | Oil Well Flow Control Equipment |

| Material: | Alloy Steel Forging | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Chiksan Swivel Joint | Working Pressure: | 15000 Psi |

| Connection: | Fig 1502 | ||

| Highlight: | wellhead connector, wellhead accessories | ||

API 6A Wellhead Integral Pipe Fittings High Pressure Chiksan swivel joints

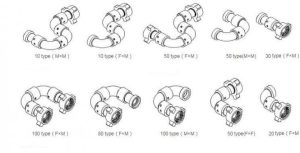

Swivel joint is a kind of high pressure fluid control equipment used in oil well cementing and fracturing service.. Hammer union of the swivel joint is to change direction and to facilitate the construction of the pipeline connecting the pipe line connection. The chiksan swivel joint is connected to high-pressure discharge line, input line, a temporary flow line, well testing, and other high-voltage transmission lines on pipelines. Various models of swivel joints and their repair kits are available, suitable for normal or low temperature, or H2S environments, with sizes ranging from 1” to 4” and related WP ranging from 2000psi to 20000psi. We can supply long and short radius swivel joints. Long radius swivel joints can minimize fluid shock, and has better performance of resistance for scouring an corrosion. We also need to use short radius swivel joint for low pressure operation due to limited installation space.Type of Chiksan swivel joint

Specification of the Swivel Joint

| Size: | 1", 1-1/2", 2", 3", 4" |

| Pressure Rating: | 6000PSI - 20000PSI |

| Material: | AISI4130/Stainless Steel |

| Temperature Class: | P-U (-29oC-121oC) |

| Performance Requirement: | PR1 |

| Product Specification Level: | PSL3 |

| End Connection: | Fig 602, Fig 1002, Fig 1502, Fig 2202 or Line Pipe Thread |

| Standard Carried: | API Spec 16C, API 6A, NACE-MR0175 |

| Application: | Wellhead Manifold Connection |

Integral Forging Tee Wellhead Connector AISI4130 High Pressure

Integral Forging Tee Wellhead Connector AISI4130 High Pressure

Description| Application: | Oil Well Fluid Control | Usage: | Wellhead Pipeline Connection |

| Material: | AISI 4130 | Production Level: | PLS 3 |

| Production Level: | PR2 | Standard: | API 6A |

| Product Name: | High Pressure Integral Tee | Connection: | Fig 1502 X Thread |

| Size: | 4" X 15000psi | Working Condiction: | Standard Serive Or Sour Service |

| Highlight: | Forging Tee Wellhead Connector, Integral Tee Wellhead Connector, AISI4130 Wellhead Connector | ||

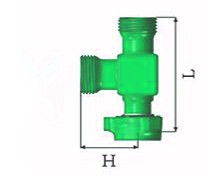

API Wellhead Tee High Pressure Integral Fitting AISI4130 Forging

The Integral Tee is a kind of wellhead integral connectors for high, low pressure and temperature and sour gas (H2S). The Integral Tees are designed and manufactured as per API Spec 6A, The integral tee includes wye and Y tee (Y shape tee),90 degree elblow, 180 degree elbow ,tee,cross,Laterals and Fishtails,with sizes of integral tee is ranging from 2" to 7" and pressures from 3000psi to 20000psi.The integral tee is made of high strength alloy steel forging with all heat-treated to enhance load-bearing capacity and lengthen service life.Integral Tees are featured with detachable wing union end connections for a high-strength, high-integrity connection.Technical parameter of integral tee

| Nominal Size | End Connections | Working Pressure Mpa/Psi | Dimensions(mm) | Service | ||

| A | B | |||||

| 2* | FIG1502 | MXFXF | 105/15000 | 308 | 154 | Standard |

| 2 | FIG1502 | MXFXM | 105/15000 | 308 | 154 | Standard |

| 2" | FIG1502 | FXFXF | 105/15000 | 308 | 154 | Standard |

| 2 | FIG1502 | FXFXM | 105/15000 | 308 | 154 | Standard |

| 2 | FIG1502 | MXMXM | 105/15000 | 308 | 154 | Standard |

| 3* | FIG1502 | MXFXF | 105/15000 | 428 | 214 | Standard |

| 3° | FIG1502 | MXFXM | 105/15000 | 428 | 214 | Standard |

| 3 | FIG1502 | FXFXF | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | FXFXM | 105/15000 | 428 | 214 | Standard |

| 3" | FIG1502 | MXMXM | 105/15000 | 428 | 214 | Standard |

| 4° | FIG1502 | MXFXF | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | MXFXM | 105/15000 | 533 | 266.5 | Standard |

| 4” | FIG1502 | FXFXF | 105/15000 | 533 | 266.5 | Standard |

| 4" | FIG1502 | FXFXM | 105/15000 | 533 | 266.5 | Standard |

| 4 | FIG1502 | MXMXM | 105/15000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXFXF | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXFXM | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | FXFXF | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | FXFXM | 140/20000 | 533 | 266.5 | Standard |

| 3" | FIG2002 | MXMXM | 140/20000 | 533 | 266.5 | Standard |

Oil Gas Well Pressure Control Sucker Rod BOP / Rod Blowout Preventer

Modekz Energy Services supply wellhead equipment, well surface testing equipment, well flow control equipment according to API 6A, API 16A, and API 16C. The main products are as below:

- Wellhead valves: Gate Valves, Plug Valves, Choke Valves, Check Valves, Mud Valves and various wellhead valve parts etc.

- Wellhead Manifold: Choke and Kill Manifold, Drilling Floor Manifold, Fracturing manifold, Well Testing Manifold.

- Wellhead Equipment: Wellhead Christmas Tree / X-Tree, Casing Head, Casing Hanger, Tubing Head,Tubing Hanger, Casing Spool, Tubing Spool, Drilling Spool etc.

- Wellhead Adapter: Spacer Spool / Riser Spool ,Flange Adapter, Union Flange, Double Studded Adapter Flange, Welded Neck Flange, Blind Flange,Companion Flange, Instrument Flange, Wellhead Clamp & Hub etc.

- Wellhead Integral Fittings: Hammer Union, Elbow, Swivel Joint, Block Cross, Block Tee, Straight Pipe, Pipe Loops etc.

- Well Pressure Control Equipment: Annular BOP, RAM BOP, Sucker Rod BOP etc

Oil Gas Well Pressure Control Sucker Rod BOP / Rod Blowout Preventer

Description

| Application: | Well Pressure Control | Usage: | Oilfield Well Production Service |

| Material Class: | AISI 4130 Forging | Production Level: | PLS 3 |

| Type: | RAM BOP | Standard: | API 16A & NACE MR0175 |

| System Working Pressure: | 3000 Psi | Product Name: | Polish Rod BOP |

| Nominal Bore: | 2 7/8” | Connection: | EUE Box -Pin |

| Highlight: | Pressure Control Sucker Rod BOP, Oil Gas Well Blowout Preventer, Oil Well Sucker Rod BOP | ||

Oil & Gas Well Blowout Preventer Sucker Rod BOP Polish ROD BOP

The Surcker Rod Blowout preventer is a kind of Rod BOP, which is designed as per API 16A for sealing of sucker-rod pump polished rod, wellhead sealing while stuffing box replacing, and for other repair work. Especially for well flooding or other natural disasters, sucker rod BOP can act for continuous well shutdown to avoid environmental pollution.

Feature

The Sucker Rod / Polish Rod BOP is designed with simple structure for convenient operation and maintaince.

The sealing of rod BOP is more reliable

With long service life

The sucker rod BOP is indispensable tool in oil field work.

Specification of Sucker Rod BOP

| Blowout Preventer 2-7/8" 3000PSI | |

| MATERIAL | CARBON STEEL |

| CONNECTION | MALE/FEMALE |

| DIE | 1-1/4" FOR PREVENT |

| POLISHED STEM SIZE | 1-1/4" |

| SPARK GAUGE SIZE | 2-7/8" |

| PRESSURE | 3000PSI |

| CONNECTING THREAD | -2-7/8" EUE (SHUT-DOWN) |

Oil Well Drilling Wellhead Casing Head For Single Completion 7/8“ X

Application: Wellhead Flow Control Equipment

Usage: Oil Well Drilling / Completion Operation

Material Class: DD-NL

Oil Well Drilling Wellhead Casing Head For Single Completion 7/8`` X

Description

| Application: | Wellhead Flow Control Equipment | Usage: | Oil Well Drilling / Completion Operation |

| Material Class: | DD-NL | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Casing Head And Tubing Head | Working Pressure: | 5000 Psi |

| Flange Size: | 9 5/8" | Process Type: | Forging |

| Highlight: | Single Completion Tubing Head, 7/8" X Casing Spool Wellhead, Oil Well Drilling Casing Spool | ||

Complete Wellhead For Single completion 9 5/8``x 5 1/2``x 2 7/8`` x 5000psi Casing Head

Casing Head is the very important equipment used in drilling process. The casing head in a conventional wellhead system is the lowest part of the wellhead assembly and is almost always connected to the surface casing string.casing head can control the wellhead pressure,casing head are often welded or screwed on the top of the conductor pipe or the casing then become a part of the wellhead system of the oil well.

Technical parameter for Complete Wellhead Casing Head

| 1 | Specification | 9 5/8"x5 1/2"x2 7/8"x5000psi |

| 2 | Material | AIS14130 |

| 3 | Material Class | DD-NL |

| 4 | Technical requirement | PSL-2,PR1 |

| 5 | Temperature Rating | LU |

| 6 | Including full set stud bolt and nuts. | Stud-A193/Gr B7,Nut-A194/Gr 2H |

| 7 | Including full set Ring gaskets | |

| 8 | Manufacturing standard | API6A |

| 9 | Documents Supplied | Material Certificate |

| Heat freatment Report | ||

| UT Report | ||

| PT report | ||

| Dimension Report | ||

| Pressure Test Report | ||

| COC |