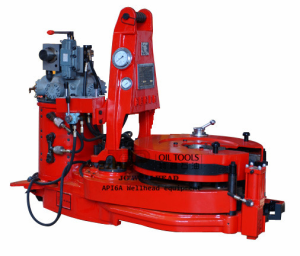

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

| Application | Wellhead Handling Tools |

| Usage | Make Up And Break Out Drilling Tools |

| Product | Pneumatic Spinning Wrench |

| Standard | API 7K |

| Condition | New |

| Function | Wellhead Automation Tools |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Oil Well Pneumatic Spinning Wrench, Spinning Wrench Wellhead Handling Tools, Wellhead Handling Spinning Wrench |

Oil Well Q250 Pneumatic Spinning Wrench Wellhead Handling Tools

Q Series Pneumatic Spinning Wrench is a pneumatically power tool capable of spinning drill pipe and collar from 31/2 to 10 inches O.D., especially used in the mechanized operation of drilling machines in shore and land oilfields instead of previous “chain” and “cord”. It’s operated more safety and with less labor power, and more efficiency. It’s more convenience to fetch core and deal with the problem underwell. The wrench’s spinning procedure is as follows: first position the wrench vertically to a joint about 11.8-19.7 inch, or just about the upset, the wrench is now swung onto pipe and it’s four drive rollers on the head clamp the pipe. Turn on air valve of air spring, to make rollers upon drill pipe, then push/pull the handle of air motors valve. Left and right motors work, and drive rollers rotate through its reducer mechanism. Drill pipe rotates for its friction. So drill pipe joint will be spinned in or out.Sepecification of Pneumatic Spinning Wrench

| Model | Q254-250 | Q254-300Y | Q254-300Y | |

|---|---|---|---|---|

| Drive mode | - | Pneumatic | - | Hydraulic |

| Size range | mm | 88.9-139.7 | 88.9-254 | 88.9-254 |

| in | 3 1/2 - 5 1/2 | 3 1/2 - 10 | 3 1/2 - 10 | |

| Air pressure | MPa | 0.5-0.9 | 0.5-0.9 | - |

| psi | 72-130 | 72-130 | - | |

| Pressure rating | Mpa | - | - | 14 |

| psi | - | - | 2000 | |

| Max. brake torque | Nm | 2000 | 2500 | 3000 |

| ft.lbf | 1475 | 1840 | 2210 | |

| Speed | RPM | 0-90 | 0-120 | 0-95 |

| Air consumption | m3/min | 10.3 | 15 | - |

| ft3/min | 360 | 529 | - | |

| Flow | LPM | - | - | 120-140 |

| GPM | - | - | 32-37 | |

| Size | mm | 1400×530×835 | 1250×570×465 | 1100×560×700 |

| in | 55×21×33 | 49×23×18 | 44×23×28 | |

| Weight | Kg | 378 | 440 | 400 |

| lb | 833 | 971 | 880 |

PLS 3 Multi Bowl / Split Unihead / Compact Type Casing And Tubing Head Assy

PLS 3 Multi Bowl / Split Unihead / Compact Type Casing And Tubing Head Assy

| Application: | Oil & Gas Well Drilling Operation | Usage: | Wellhead Pressure Control |

| Material Class: | DD-NL | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Casing Head Spool Assembly | Working Pressure: | 3000 Psi |

| Nominal Flange Size: | 20 3/4" | Process Type: | Forging |

| Highlight: | Compact Type Casing And Tubing Head, API 6A Multi Bowl Tubing Head, Split Unihead Casing Head PLS 3 | ||

Multi Bowl/Split Unihead / Compact type Casing and Tubing Head Assy

The Tubing head is the important parts of the wellhead equipment and connected with Christimas Tree, the buging head is designed with universal straight hold and conformed with API 6A Specification, which can be fitted with all types of single or double-string completion tubing hanger.

Wellhead Product scope

| Wellhead valves |

Gate Valves, Plug Valves, Choke Valves, Check Valves,

Mud Valves and various wellhead valve parts etc. |

| Wellhead Manifold |

Choke and Kill Manifold, Drilling Floor Manifold, Fracturing manifold,

Well Testing Manifold. |

| Wellhead Equipment |

Wellhead Christmas Tree / XTree, Casing Head, Casing Hanger,

Tubing Head,Tubing Hanger, Casing Spool, Tubing Spool, Drilling Spool etc. |

| Wellhead Adapter |

Spacer Spool / Riser Spool ,Flange Adapter, Union Flange,

Double Studded Adapter Flange, Welded Neck Flange, Blind Flange, Companion Flange, Instrument Flange,Wellhead Clamp & Hub etc. |

| Wellhead Integral Fittings |

Hammer Union, Elbow, Swivel Joint, Block Cross, Block Tee,

Straight Pipe, Pipe Loops etc. |

| Well Control Equipment | Annular BOP, RAM BOP, Sucker Rod BOP, BOP Stack, Wireline BOP etc |

| Surface Well Testing Package |

Surface Test Tree (Flowhead), Surface Safety Valve(SSV), ESD System,

Data Header, Choke Manifold, Oil Diverter manifolds, Gas Diverter Manifold |

Multi Bowl/Split Unihead type Casing and Tubing Head Assembly consisting of

| 1 | Lower Spool 13 5/8" 5M Flanged top × 20 ¾ " 3M flanged bottom, two 2 1/16 " 5M studded, 1 ½" LP VR Plug threaded Side Outlets. |

| 2 | Top Spool 13 5/8 " 5M top × 13 5/8 " 5M bottom 2 1/16 " 5M studded, 1 ½ " LP VR Plug threaded Side Outlets. |

| 3 | Bottom flange of bottom spool fitted with Seal for extended neck of 13 3/8" casing, top housing for landing Mandrel type standard Hanger and Seal or emergency Slip and Seal assembly for 9⅝" Casing. |

| 4 | Top Spool bottom flange prepared for secondary seal of extended neck of 9 5/8 " Mandrel Hanger/ Casing, top housing to land 13⅝" nom. Tubing Hanger and Seals, Lock Down Screws. |

| 5 | API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. |

| 6 | Tubing Hanger: Extended Neck Type Tubing Hanger and Seals, 13 ⅝" 5M, Matching with Multi Bowl Upper Housing, 3½², 9.2 lb/ft, N/L-80, Vam Top box up x pin down connection . 4" Cameron type ‘H’ BPV thread profile and ¼ " NPT SCSSSV control line port complete with Seals. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. |

| 7 | Test plugs to seat in Lower Housing, 4 ½ IF Box Up × Pin Down Connection complete with seals. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. |

| 8 | Mandrel Casing Hanger for 9 5/8 " Casing, 9 5/8 ", 43.50 lb/ft Premium Box Down connection HSM-2 to land in lower spool housing (with Seals if required) API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. |

| 9 | Gate Valve: 2 1/16" 5M manual Gate Valves, Bi-Directional Flow with hand wheels. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4, PR2, Appendix ‘F’. |

| 10 | Blind Flange: 2 1/16" 5M blind flange, ½ " NPT tapped. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. ( 2 no. fitted, 2 no. loose) |

| 11 | Adapter: 2 1/16" 5M flange, 2" fig 1502 Integral Weco Union fitted with Blind Pin Plug. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4.( supply loose) |

| 12 | Adapter Integral, 2 1/16 " 5M flanged with 2" fig 1502 Weco Union with Blind Pin Plug. API spec. 6A latest edition, Material Class ‘BB’, Temperature Level ‘U’, PSL-4. ( loose) |

Wellhead Product scope

| Wellhead valves |

Gate Valves, Plug Valves, Choke Valves, Check Valves,

Mud Valves and various wellhead valve parts etc. |

| Wellhead Manifold |

Choke and Kill Manifold, Drilling Floor Manifold,

Fracturing manifold, Well Testing Manifold. |

| Wellhead Equipment |

Wellhead Christmas Tree / XTree, Casing Head,

Casing Hanger, Tubing Head,Tubing Hanger, Casing Spool, Tubing Spool, Drilling Spool etc. |

| Wellhead Adapter |

Spacer Spool / Riser Spool ,Flange Adapter, Union Flange,

Double Studded Adapter Flange, Welded Neck Flange, Blind Flange,Companion Flange, Instrument Flange,Wellhead Clamp & Hub etc. |

| Wellhead Integral Fittings | Hammer Union, Elbow, Swivel Joint, Block Cross, Block Tee, Straight Pipe, Pipe Loops etc. |

| Well Control Equipment | Annular BOP, RAM BOP, Sucker Rod BOP, BOP Stack, Wireline BOP etc |

| Surface Well Testing Package |

Surface Test Tree (Flowhead), Surface Safety Valve(SSV),

ESD System, Data Header, Choke Manifold, Oil Diverter manifolds, Gas Diverter Manifold |

Q13 3/8-25 1/2/35 API 7K Manual Casing Tong Drill Pipe Handling Tools Alloy Steel

| Application | Making Up/Breaking Out Casing |

| Usage | Oilfield Handling Tools |

| Product | Casing |

| Standard | API 7K |

| Process Type | Cast |

| Condition | New |

| Size | Q 13 3/8 - 25 1/2 - 35 |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | drill pipe handling equipment, drill pipe handling tools |

Oil Well Handling Tools Manual Tong Type DB

The manual tongs are designed and manufactured in accordance with the National Standard for the Petroleum and National Gas Industry GB/T17744, SY/T5074-2012“Elevator links,elevators,tongs”which is a useful tool applied to make up and break out drill pipes, coupling hoop of the drill pipe ,joint, casings , casings hoops etc. When raise drill tool up and fall it down. Changing lug jaws and handling shoulders or hole can adjust the handling size of the tongs According to the requirements of the usage different torque’s tongs can be chosen.Q13 3/8-25 1/2/35 API 7K Manual Casing Tong Drill Pipe Handling Tools Alloy Steel

| Model | No. of Latch Lug Jaw | Size Range in | Rated Torque (kN·m) |

|---|---|---|---|

| 13-3/8”~25-1/2”-35 | 9, 8 | 13-3/8”~14-1/2” | 35 |

| 8, 7 | 14-1/2”~16” | ||

| 8, 9, 9 | 16”~17-1/2” | ||

| 8, 9, 7 | 17-1/2”~19” | ||

| 7, 8, 7 | 19”~20” | ||

| 9, 8, 9, 7 | 20”~21-1/2” | ||

| 9, 7, 8, 7 | 21-1/2”~23” | ||

| 9, 9, 8, 7, 7 | 24”~25-1/2” | ||

| 9, 8, 7, 7, 7 | 25-1/2”~27” | ||

| 8, 7, 7, 7, 7 | 27”~28-1/2” | ||

| 9, 9, 8, 7, 7, 8 | 28-1/2”~30” | ||

| 9, 7, 7, 7, 7, 8 | 9, 7, 7, 7, 7, 8 | 30” | |

| Model | No. of Latch Lug Jaw | Size Range in | Rated Torque (kN·m) |

| 25-1/2”~36”-35 | 9, 8, 7, 7, 7 | 25-1/2”~27” | 55 |

| 8, 7, 7, 7, 7 | 27”~28-1/2” | ||

| 9, 9, 7, 7, 7, 8 | 28-1/2”~30” | ||

| 9, 7, 7, 7, 7, 8 | 30”~31-5/8” | ||

| 8, 9, 8, 9, 7, 7 | 31-1/2”~33” | ||

| 7, 9, 8, 9, 9, 7, 8, 9 | 33”~34-1/2” | ||

| 8, 7, 7, 9, 9, 8, 8, 8 | 34-1/2”~36” |

Single RAM Quad Coiled Tubing BOP For Oil Well 4 1/16″ X 10000psi

More specification are available according to customer's requirement.

Product scope

| Wellhead valves | Gate Valves, Plug Valves, Choke Valves, Check Valves, Mud Valves and various wellhead valve parts etc. |

| Wellhead Manifold | Choke and Kill Manifold, Drilling Floor Manifold, Fracturing manifold, Well Testing Manifold. |

| Wellhead Equipment | Wellhead Christmas Tree / XTree, Casing Head, Casing Hanger, Tubing Head,Tubing Hanger, Casing Spool, Tubing Spool, Drilling Spool etc. |

| Wellhead Adapter | Spacer Spool / Riser Spool ,Flange Adapter, Union Flange, Double Studded Adapter Flange, Welded Neck Flange, Blind Flange,Companion Flange, Instrument Flange,Wellhead Clamp & Hub etc. |

| Wellhead Integral Fittings | Hammer Union, Elbow, Swivel Joint, Block Cross, Block Tee, Straight Pipe, Pipe Loops etc. |

| Well Control Equipment | Annular BOP, RAM BOP, Sucker Rod BOP, BOP Stack, Wireline BOP etc |

| Surface Well Testing Package | Surface Test Tree (Flowhead), Surface Safety Valve(SSV), ESD System, Data Header, Choke Manifold, Oil Diverter manifolds, Gas Diverter Manifold |

Single RAM Quad Coiled Tubing BOP For Oil Well 4 1/16`` X 10000psi

| Application: | Oil Well Pressure Control | Usage: | Oil Well Coiled Tubing Operation |

| Bore Size: | 4 1/16" | Type: | Coiled Tubing Combi BOP |

| RAM: | Single RAM | Standard: | API 16A |

| Working Pressure: | 10000 Psi | Specification: | 4 1/16" X 10000psi |

| Highlight: | Single RAM Coiled Tubing BOP, Oil Well Coiled Tubing BOP, 1/16" Quad BOP Coiled Tubing | ||

Oil Well API Coiled Tubing BOP Combi BOP 4 1/16`` x 10000psi Quad BOP

Specification of Coiled Tubing Combi BOP

| Model | Main Bore | Tubing Size | Rated Pressure

(psi) |

Max. Hydraulic Pressure (psi) |

| 3 1/16"-10K | 3 1/16" | 1"- 2" | 10,000 | 3,000 |

| 4 1/16"-10K | 4 1/16" | 1"-2 3/8" | 10,000 | 3,000 |

| 4 1/16"-15K | 4 1/16" | 1"-2 3/8" | 15,000 | 3,000 |

Specification of Coiled Tubing Quad BOP

| Model | Main Bore | Tubing Size | Rated Pressure (psi) | Max. Hydraulic Pressure (psi) |

| 2 9/16"-10K | 2 9/16" | 1"-1 1/2" | 10,000 | 3,000 |

| 3 1/16"-10K | 3 1/16" | 1"-2" | 10,000 | 3,000 |

| 4 1/16"-10K | 4 1/16" | 1"-2 5/8" | 10,000 | 3,000 |

| 4 1/16"-15K | 4 1/16" | 1"-2 5/8" | 15,000 | 3,000 |

| 4 1/16"-20K | 4 1/16" | 1"-2 7/8" | 20,000 | 3,000 |

| 5 1/8"-10K | 5 1/8" | 1"-2 7/8" | 10,000 | 3,000 |

| 5 1/8"-15K | 5 1/8" | 1"-2 7/8" | 15,000 | 3,000 |

Surface Well Testing Wellhead Manifold With Choke Valves 3 1/8″ X 5000#

Surface Well Testing Wellhead Manifold With Choke Valves 3 1/8" X 5000#

Description| Application: | Surface Well Gas Testing | Usage: | Oil Well Flow Control Equipment |

| Material Class: | DD-NL | Production Level: | PLS 3 |

| Temperature Rating: | PU | Standard: | API 16C |

| Product Name: | Well Gas Testing Choke Manifold | Working Pressure: | 10000 Psi |

| Specification: | 3 1/8" X 5000# | ||

| Highlight: | oil well testing equipment, surface test tree | ||

Surface Well Testing Manifold with choke valves API 16C Gas Testing Manifold

The gas testing manifold is a kind of surface well testing equipment, it is the high pressure well manifold used for controlling the fluid pressure and flow, normally manifold offers the option of directing flow through either choke while isolating the other for choke changes, maintenance or repair. The gas testing manifold is designed and manufactured according to API 16C.Structure of gas testing manifold

The inlet of the gas testing manifold is a flange union 3 1/8"-5K * 3"Fig602F, outlet is a threaded flange 3 1/8"-5K-3"FIG602M. The manifold consists of a manual adjustable choke valve, a positive choke valve, Manual Gate valve WKM , Block Tee, Block Cross etc., the manifold will be tested as per standard API 16C. The valve installed in the manifold is WKM type, and the gas testing manifold is in easy operation that can meet the requirements of oilfield testing requirements. Manual gate valve is the main part of the gas testing manifold, consist of valve body, valve Bonnet, valve stem and valve seat etc., Manual choke valve is the key parts of the manifold, The valve is operated by personnel, Needle assemble and valve seat seals are made by wear resistance special material, the valve featured large body and needle type valve core with large flow, can reduce the shock during chocking, also lower the noise.Technical parameter of the wellhead choke manifold

| Bore Diameter | 3 1/8" |

| Pressure Rating | 5000psi/35Mpa |

| Performance Specification Level | PSL3 |

| Performance Requirement | PR2 |

| Material Class | EE |

| Temperature rating | PU |

WECO Piping Wellhead Hose AISI 4130 Integral Pup Joint

WECO Piping Wellhead Hose AISI 4130 Integral Pup Joint

Description| Application: | Oil Well Flow Control Operation | Usage: | Chicksan Swivel Loop |

| Material: | AISI 4130 Forging | Production Level: | PLS 3 |

| Temperature Class: | U | Standard: | API 6A |

| Product Name: | Pup Joint For Wellhead Hose | Working Pressure: | 6000 Psi |

| Connection: | Hammer Union Fig 602 | ||

| Highlight: | WECO Piping Integral Pup Joint, AISI 4130 Integral Pup Joint, Wellhead Hose Integral Pup Joint | ||

API 16C Integral Pup Joint With Hammer Union High Pressure WECO Piping

The Integral Pup joints are the part of cementing and fracturing equipment, which is used to tranport high pressure flow in fracturing manifold, cementing manifold,maintenance manifold and test manifold in the acidic operating environment. The Integral Pup Joints are straight tubes / straight pipes with hammer union, thread or flange connections on both ends, The Integral Pup joints are made of high strength steel, with a special toughening process. It uses Acme threaded connection, making it with the demolition convenient, fast, reliable connection, and reliable. Multiple seal design and high precision, to ensure the sealing performance of Pup joint.Specification of the pup joint and crossover sub

| Description | |

| HIGH PRESSURE WECO PIPING | |

| 1 | Pup Joint 3" FIG 602 Male x Male OAL-2 Ft. H2S |

| 2 | Pup Joint 3" FIG 602 Male x Female OAL-10 Ft.H2S |

| 3 | Pup Joint 3" FIG 602 Male x Female OAL-5 Ft. H2S |

| 4 | Pup Joint 3" FIG 602 Male x Female OAL-3 Ft.H2S |

| 5 | Pup joint 3" FIG 602 Male x Female OAL-2 Ft H2S |

| 6 | Elbow Swivel, Style 10 3" FIG 602 MALE X FEMALE H2S |

| 7 | Elbow Swivel, Style 10 : 3" FIG 602 MALE x MALE H2S |

| 8 | Union 3" FIG 602 End connection EUE Box H2S |

| 9 | 3" FIG 602 Female Seal. H2S |

| 10 | Crossover 3" FIG 1502 FEMALE x 3" FIG 602 FEMALE H2S |

| 11 | Crossover 3" FIG 602 FEMALE x 3-1/2” EUE PIN OAL-5 Ft. H2S |

| 12 | Crossover Assembly, 4-1/2" EUE-8rd Pin x 3" Fig 602 Female c/w seal, 6000 PSI, STD Service, Material AISI 4130, 10" long, c/w thread protectors |

| 13 | Crossover Assembly, 4-1/2" EUE-8rd Pin x 3" Fig 602 Male c/w nut, 6000 PSI, STD Service, Material AISI 4130, 10" long, c/w thread protectors |

| 14 | Pup Joint Assembly, 3" Fig 602, MxF union ends, 6000 PSI, Std. Service c/w nut, retainer ring, segment & rubber seal, Material AISI 4130, 10 ft long |

ZQ Series Handling Tools Oilfield Drill Pipe Hydraulic Power Tong API

ZQ Series Handling Tools Oilfield Drill Pipe Hydraulic Power Tong API

| Category | Details |

|---|---|

| Application | Drilling Service |

| Usage | Oilfield Handling Tools |

| Product | Drill Pipe Power Tong |

| Standard | API 7K |

| Condition | New |

| Function | Make Up and Breaking Out of Drill Pipes |

| Material | Alloy Steel |

| Working Condition | Standard Service |

| Highlight | Handling Hydraulic Power Tong, Drill Pipe Hydraulic Power Tong, API Compliant |

ZQ Series Drill Pipe Hydraulic Power Tong API Oilfield Handling Tools

ZQ Drill Pipe Power Tong is an ideal wellhead handling tool for oil and gas well drilling operation, the power tong is widely applied in making-up and breaking-out for well drilling and repairing on offshore and land. Open-throat design of the ZQ series with high mobility allows escaping from drilling pipe freely. The tong is a combination of spinning tong and torque tong. It substitutes cathead, suspension tong and spinning rope in making-up and breaking-out. The tongs are designed and manufactured according to API Spec 7KSEPCIFICATION OF DRILL PIPE POWER TONG

| Model | ZQ127-25 | ZQ162-50 | ZQ203-100 | ZQ203-125 | |

|---|---|---|---|---|---|

| Size range | mm | 65-127 | 85-162 | 127-203 | 127-203 |

| in | 2 3/8 coupling - 3 1/2 coupling | 2 3/8 coupling - 5 coupling | 3 1/2 coupling - 8 body | 3 1/2 coupling - 8 body | |

| Max.torque | KN.m | 25 | 50 | 100 | 125 |

| ft.lbf | 18440 | 36880 | 73750 | 92200 | |

| Speed(High ger) | rpm | 65 | 60 | 40 | 40 |

| Speed(Low ger) | rpm | 10.5 | 4.1 | 2.7 | 2.7 |

| Air pressure | Mpa | 0.5-1 | |||

| psi | 72-144 | ||||

| Pressure rating | Mpa | 12 | 16 | 16.6 | 20 |

| psi | 1740 | 2320 | 2400 | 2900 | |

| Flow rating | L/min | 120 | 120 | 114 | 114 |

| gpm | 31.7 | 31.7 | 30 | 30 | |

| Shifting distance | mm | 1000 | 1000 | 1500 | 1500 |

| in | 39.4 | 39.4 | 59 | 59 | |

| Lifting distance | mm | - | 0-440 | 0-430 | - |

| in | - | 0-17.3 | 0-17 | - | |